How Long Should It Take For A Thermocouple To Register

Contents

- one Introduction

- 2 Choosing a Thermocouple

- 2.i Conductor Scale Types

- 2.ane.one Using Other Thermocouple Types with Phidgets

- ii.2 Junction Type

- ii.ii.one Ungrounded

- ii.2.2 Grounded

- 2.2.three Exposed

- 2.i Conductor Scale Types

- 3 Things to Picket For

- iii.1 Grounding

- 3.2 Polarity

- 3.3 Interference

- three.4 Wire Size

- 3.5 Wire Length

- 4 How to connect your Thermocouple

- 4.ane Stripped Wire

- 4.two Connectors

Introduction

A thermocouple is a device consisting of 2 different conductors that produce a voltage proportional to a temperature deviation betwixt either terminate of the pair of conductors. There are many types of thermocouples, with varying types of conductors and probe designs.

Nigh thermocouples produce voltages of less than 50mV and so very sensitive electronics are required to interface with them.

Choosing a Thermocouple

Conductor Calibration Types

J, K, E and T-Type thermocouples are the virtually mutual types of thermocouples. Each type has a dissimilar temperature range and resolution due to the metals used in the conductors.

Calibration Type Temperature Ranges:

| Type | Temperature Range °C | Notes |

| Thousand | -200 to +1250 | The most mutual sensor, broad range, good in oxidizing temper |

| J | 0 to +750 | More Limited range, main awarding is with onetime equipment that cannot take modern thermocouples |

| T | -200 to +300 | Most Accurate base-metal thermocouple, non-magnetic, popular choice for strong magnetic fields and subzero environments |

| E | -200 to +900 | Well suited to low temperature (cryogenic) utilise |

The insulation that surrounds the thermocouple is the limiting factor in the true temperature range. For example, a K-type thermocouple insulated with teflon is adept up to +200°C. The aforementioned thermocouple using Fiberglass is practiced to 480°C. For short durations the thermocouples tin can exist exposed to higher heat than they are rated for, however, they will degrade if exposed to very high estrus for long periods of fourth dimension.

Using Other Thermocouple Types with Phidgets

You can interface with other thermocouple types using Phidgets Inc. thermocouple interfaces, with some small-scale calculations:

- First, visit this website and open the conversion table for the desired thermocouple type.

- Take the ambient temperature value measured by the board and use the ones digit to select the column, and the other digits to select the row. Record this thermoelectric voltage value.

- Open your Phidget's thermocouple output in VoltageInput manner and read the Voltage belongings in your program (see the Phidget22 API for details) in guild to go the thermocouple's current thermoelectric voltage value.

- Add the two voltage values from the previous steps and utilise the table to catechumen back into temperature.

Junction Type

Junction Types

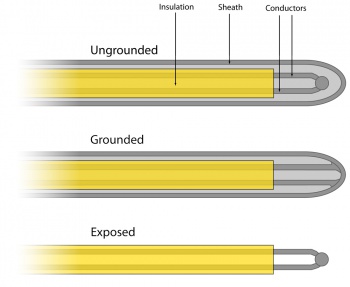

A cross-sectional view of the three most common junction types.

Full-sized Image

An important feature to consider when choosing a thermocouple is the junction blazon. This describes the degree to which the sensing terminate of the thermocouple is exposed to the surround it's measuring. There are three main types of junctions: Grounded, Ungrounded, and Exposed.

Ungrounded

A thermocouple with an ungrounded junction has a metallic outer sheath, usually made of a corrosion-resistant material such as stainless steel. The junction where the 2 conductors see is suspended inside this sheath, such that the end of the junction is not in contact with the sheath. Equally a upshot, it will accept longer for the thermocouple to react to temperature changes in the surroundings, because the inside of the sheath must reach thermal equilibrium earlier the conductors tin can find the change. Ungrounded thermocouples tin can be used with a Phidgets Inc. thermocouple interface with no issues equally long as the type is also supported.

Advantages:

- The conductors are protected from the environment, enabling the sensor to be used in a wider range of applications.

- Since the conductors are not grounded, the thermocouple will not introduce a ground loop into the system.

Disadvantages:

- It takes longer for the thermocouple to react to temperature changes in the surroundings because it is not in direct contact with it.

Grounded

A thermocouple with a grounded junction has an outer sheath merely like the ungrounded design, only the junction where the two conductors meet is welded to the inside of the sheath. This allows for a shorter reaction time to temperature changes, but is likely to introduce a ground loop into the organisation. In gild to use a grounded thermocouple with a Phidgets Inc. thermocouple interface, should use an isolated thermocouple interface or a USB isolator to ensure organization stability.

Advantages:

- The conductors are protected from the surround, enabling the sensor to be used in a wider range of applications.

- Reacts more than quickly to temperature changes in the environment.

Disadvantages:

- Special care must be taken to protect your system'southward stability from footing loops.

Exposed

A thermocouple with an exposed junction has no protective sheath, allowing the junction where the 2 conductors meet to be in straight contact with the environment it'south measuring. As a result, an exposed thermocouple will take the fastest reaction time, but can simply exist used in non-corrosive, non-pressurized applications (While it is possible to use exposed thermocouples in loftier pressure applications, information technology is hard to make a proper seal. Many enclosed thermocouples will have special hardware for this sort of application). Exposed thermocouples can be used with a Phidgets Inc. thermocouple interface with no issues as long as the type is too supported.

Advantages:

- Exhibits the fastest reaction to temperature changes in the environment due to direct contact.

- Since the conductors are not grounded, the thermocouple will not innovate a ground loop into the organisation.

Disadvantages:

- Limited to non-corrosive, not-pressurized applications.

- The thermocouple has no protection from physical contact.

Things to Watch For

Grounding

A "ground loop" happens when ii points in a excursion are at different potentials, when they are expected to exist the same. This difference in electrical potentials causes a build upwardly of static electricity that can requite electric shocks to people and electronics. In the case of thermocouples and not-isolated thermocouple boards, the negative or footing terminal on the board is USB footing. And then, if you ground the junction of your thermocouple when using these boards and the textile it's affixed to has a different voltage than the ground on the estimator, you've created a excursion with two points at different potentials. This problem can exist avoided entirely if you use an isolated thermocouple board such equally the TMP1100 - Isolated Thermocouple Phidget. More information about how to avert ground loops in thermocouples can exist found here, on the Phidgets blog.

Polarity

Each thermocouple has a positive and a negative lead. If you hook information technology upwards with the contrary polarity, you will experience unpredictable readings and incorrect temperatures. Always brand sure proper polarity is maintained at each junction and connector along your thermocouple.

Interference

When measuring from a thermocouple, each thermocouple is compared to adapter'southward internal ground. If your thermocouple is measuring a conductive device which cannot equalize to the ground of the adapter, you should isolate the thermocouple wire using thermally conductive epoxy. Thermocouples are conductive, and are very good at shorting electric systems together. If in doubt, exercise not allow the thermocouple wire to contact other metal parts.

Since a thermocouple is essentially only two long wires, it could act like an antenna and pick upward electromagnetic interference from other nearby electronics or appliances. See the hardware reliability page for more data on how to deal with this problem.

Wire Size

The maximum temperature varies with the diameter of the wire used in the thermocouple. Although the type of thermocouple dictates the temperature range, the maximum range is also limited by the bore of the thermocouple wire. That is, a very sparse thermocouple may not reach the full temperature range. On the other paw, a thinner thermocouple does reduce the corporeality of thermal distortion introduced.

Selecting the wire gauge used in the thermocouple sensor depends upon your application. Generally, when longer life is required for the higher temperatures, the larger size gauges should exist chosen. When sensitivity is the prime concern, the smaller sizes should be used.

Wire Length

Very long thermocouples are okay (even 100m), but if there are measurement stability issues or USB resets, ferrite beads can be added to the thermocouple wire close to the adapter. See our tutorial on improving hardware reliability for more than information.

Note that thermocouples use special wires. This ways that if y'all want to extend the length of your thermocouple you need to use thermocouple wire of the same letter type, not just generic wire. Often, thermocouple extension wire will be rated for a narrower temperature range, since it isn't intended to be used in the sensing end of the awarding.

Since a thermocouple works due to the interaction at the junction of 2 unlike metals, it isn't advisable attach two pieces of thermocouple wire just by soldering them- This would create an additional junction that would interfere with the measurement signal. The best way to connect two thermocouple wires is to buy a connector of the aforementioned letter type that clamps onto either cease, such every bit this Thou-blazon connector from Omega.

On the flip side, y'all can cut thermocouples down to a shorter length if y'all require that as well. Simply make sure to cut the size yous want out of the side with the actual sensing area on information technology. The junction between the ii metals is what allows the device to measure out temperature and then you need to have the finish with the junction on the length you will exist using or the thermocouple won't do anything.

How to connect your Thermocouple

Stripped Wire

Most thermocouples come up with the leads but stripped and otherwise unaltered. We recommend a 5 to 6mm wire strip length; the final blocks on the majority of adapters will accept wires betwixt 16 - 26 AWG. When using thin wires, make sure that you have a solid connectedness after tightening the final spiral.

Connectors

Many K-Blazon thermocouples are designed to mate with the Subminiature (flat pin) female connector. Listed below are examples of compatible thermocouples from pop sensor manufacturers using this connector.

Compatible Thermocouples:

| Manufacturer | Part Number | Clarification |

| Omega | TC-PVC-K-24-180 | PVC-insulated 4.5m epoxy-coated tip k-type |

| Omega | 88202K | Moving-surface swivel-head handle thousand-type |

| Omega | 88402K | Flat-leaf magnetized yard-type |

| Nanmac | B8-10 | Handheld trident-style ribbon k-type |

| Cole-Parmer | WU-93631-eleven | ICONEL-sheathed high-temp 12" k-type |

How Long Should It Take For A Thermocouple To Register,

Source: https://www.phidgets.com/docs/Thermocouple_Primer

Posted by: hollomanformiscrad.blogspot.com

0 Response to "How Long Should It Take For A Thermocouple To Register"

Post a Comment